| |

|

| |

| Benefits |

| |

- Provide maximise strength and steady spans.

- Accurately roll-formed to ensure dimensional precision.

- Economical substitute to timber battens.

- Resistance to termite attack.

- Highly cost effective.

- User friendly installation method.

- Cutting to length available.

- Proven durability and worthiness

|

|

|

|

| |

Specifications

|

| |

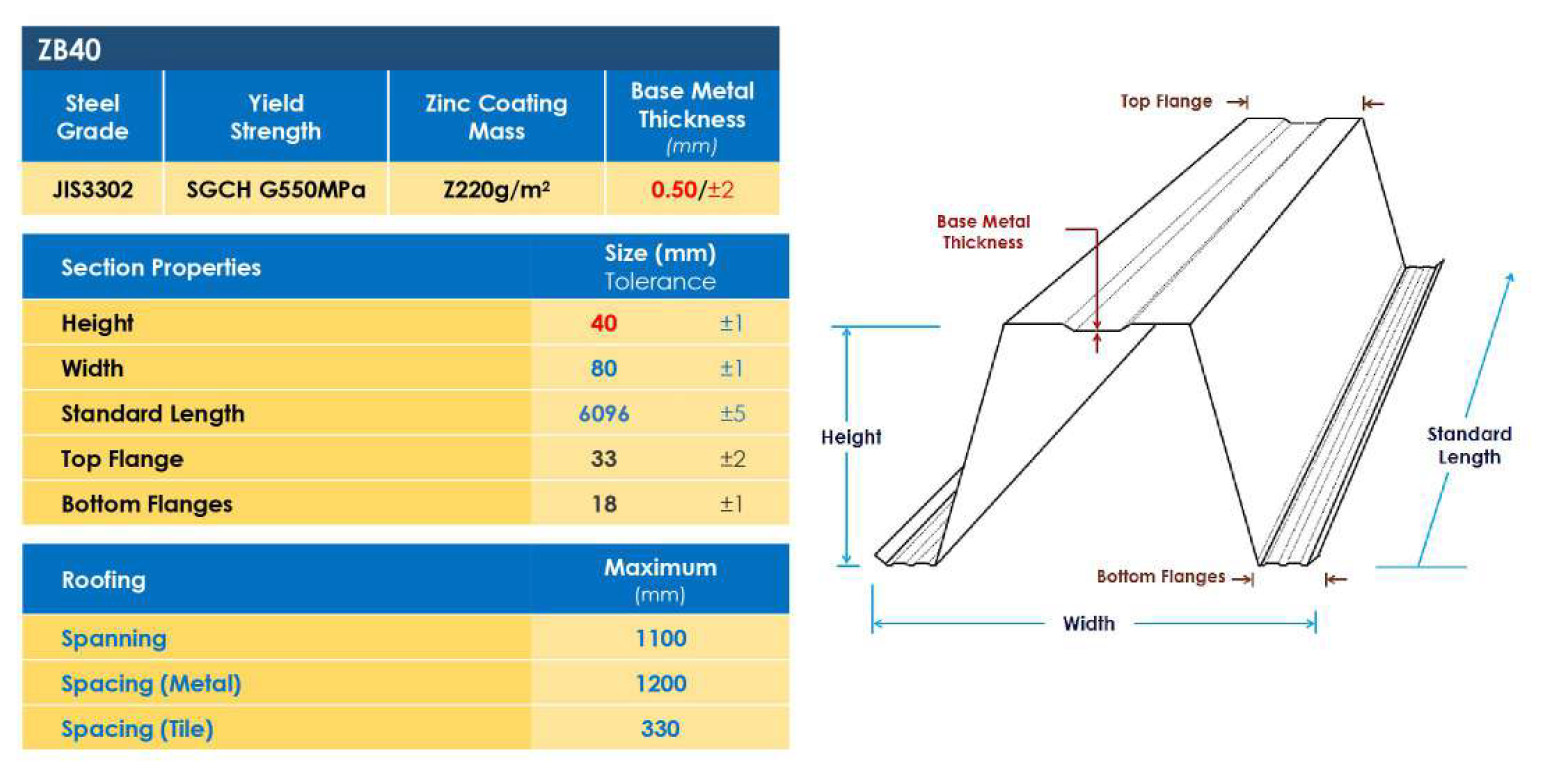

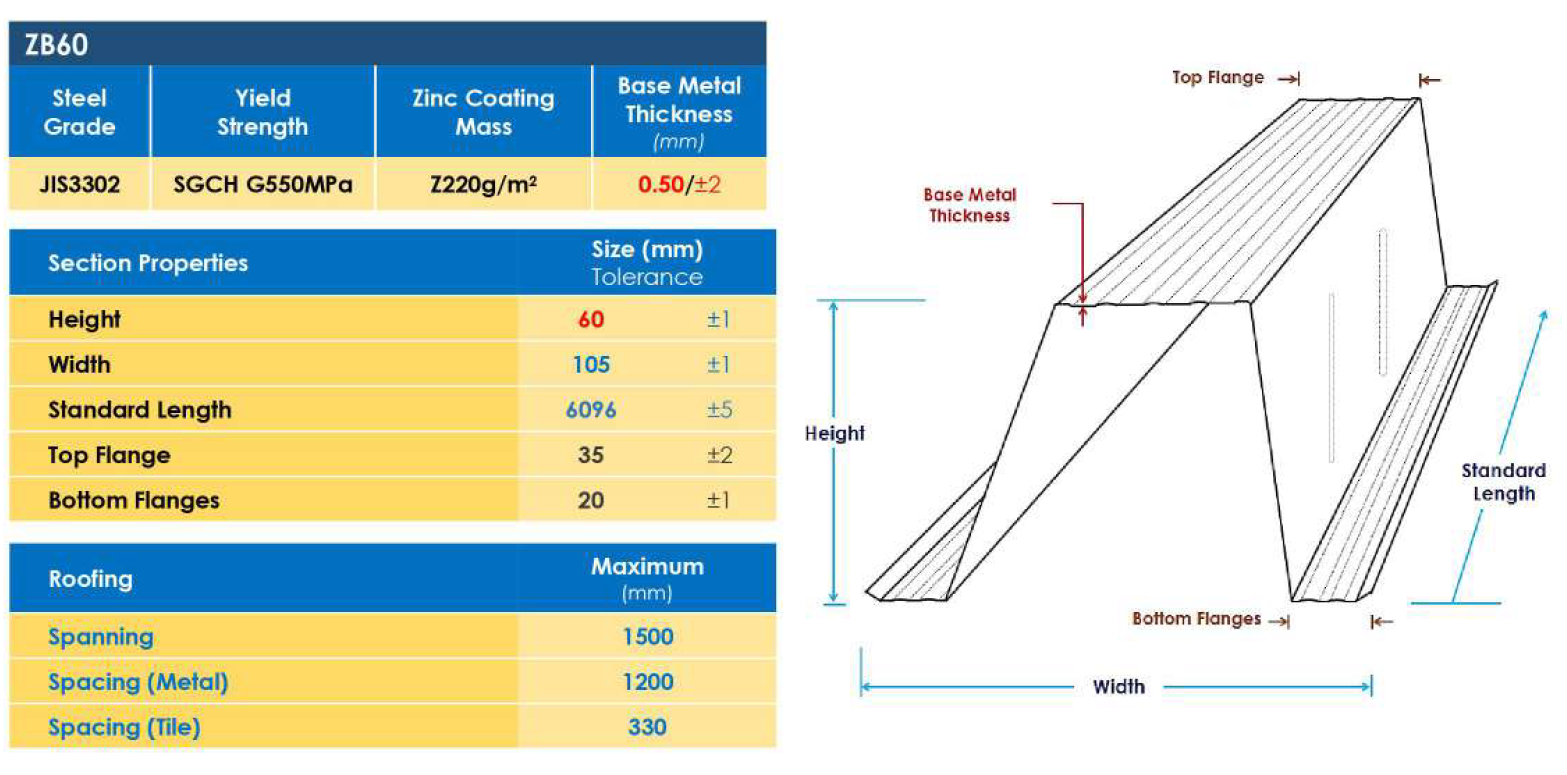

| Specification |

| |

| Zin Battens are produced from Hi-Tensile material with exterior protection coating Z220 and compliance with Japanese Industrial Standards 3302. |

| |

| Batten Profiles |

| |

.jpg) |

|

|

| |

| Section Properties |

| |

| The above data is guideline only, may varies subject to individual Structural Engineer Design. |

| |

| Standard Length |

| |

| Each Zin Roof Batten standard pack contains 6.1m x 100 pieces. Nevertheless it can also be cut in the factory to any length specified by the customer. |

| |

| Tolerable Wind Pressure |

| |

| The batten spacing must not exceed the manufacturers maximum recommended support spacing for the roof cladding material. These values are for buildings located under the following conditions as specified by AS1170. |

| |

.jpg) |

| |

Installation

|

| |

| Roof battens are thin strips of material that made of Galvanised or Aluminum Zinc. They’re installed before the roof is laid. The ideal installation method for roof battens when installing a roof depends on the roof profile, its slope, and environmental conditions such as rainfall, temperature and wind. |

| |

| Fixing Details |

| |

.jpg) |

| |

| Fastener Identification |

| |

.jpg) |

| |

| Structural Lap |

| |

| To minimize each cutting process, lay the battens in one direction starting from one end of the roof. The overlap must be supported over a truss or rafter. We recommend use our own ZinTruss C purlins to achieve maximum performance and material compatibility. |

| |

| Fastener Position |

| |

| Fastener position-screws must be located as shown in the illustration of the overlap battens. |

| |

.jpg) |

| |

| Battens Spacing |

| |

| The ideal orientation and spacing of battens depends on the roof design and the environmental conditions it must endure. They may be oriented at right angles to the trusses or rafters, or they may be installed parallel to the slope of the roof. Some roofs may require a grid of battens that run in both directions. This is known as a counter-batten system. The slope of the roof often dictates what batten system will be used. A local building codes may require battens and dictate how they must be installed. |

| |

.jpg) |

| |

| Roofing Selection |

| |

| Our factory made metal roofing profiles such as ZinDek, ZinSpan, ZinLok and ZinEverroof have been fully tested on compatibility with Zin Roof battens. If you have a technical question that you would like resolved, contact our technical team for expert advice. |

| |

Precautions

|

| |

Transport and Storage Transport and Storage |

|

| Battens nest together for easy transport and storage. Store battens in bundles, preferably indoors. If this is not possible, store off the ground, allow to drain properly and cover from the weather. |

| |

Storing On-Site Storing On-Site |

|

| Battens are delivered in strapped bundles. If not required for immediate use, the bundles should be neatly stacked clear of the ground. When stacked they should be allowed to drain, should wetting occur. The bundles should not be exposed in the open for extended periods. If unavoidable, protect from rain and moisture with waterproof covers. |

| |

Cutting Cutting |

|

| Cut each batten using a non-abrasive disc or metal cutting blade. Swarf and burred edges should be cleaned off on completion of cutting. |

| |

Safety Safety |

|

The installation of roofing batten can be hazardous, and will require an adequate safety plan be in place prior to handling or installing of these products. We recommend that good trade practice be followed. Our battens are not designed to be walked on unless fully covered by correctly installed materials or the correct grade of safety mesh.

The manufacturing or delivery process may result in oil or grease adhering to these battens which could increase the potential hazard.

Handling of this product must be carried out using a correctly supervised crane or appropriate lifting device. Safety harnesses must always be used during installation of purlins, battens and roof panels when working off the ground, and under no circumstances must any body weight be placed on roof panels, purlins, or battens that have not been fully fastened into position. |

| |