| Features

|

|

|

- Industrial Grade

- Permanently Flexible

- Indoor and Outdoor Use

|

|

|

|

| Available Colors

|

|

|

- Clear

- White

- Grey

- Black

- Bronze

|

|

|

|

|

|

|

| Packaging

|

|

|

- 300 ml (cartridge)~24/carton

|

|

|

|

| Storage

|

|

|

- Store in a dry and cool place with temperature below 30 °C.

- Use within 12 months from date of production.

|

|

|

|

|

|

|

| Specifications/Compliances

|

|

|

Low VOC

- USEPA Method 24 and SCAQMD Method 303-91 (SCAQMD rule 1168)

|

|

|

| Product Specification

|

|

|

| Curing System

|

Appearance

|

| Odour

|

| Specific Gravity

|

| Slump (ASTM D2202)

|

| Tensile Strength (ASTM D412)

|

| Elongation at Break (ASTM D412)

|

| Shore A Hardness (ASTM C661)

|

| Tack-free Time

|

| VOC Content (USEPA Test Method 24)

|

| Application Temperature

|

| Service Temperature

|

|

| : Moisture Curing, Acetoxy

|

: Paste (Before Curing)

: Elastic Rubber (After Cured)

|

| : Vinegar-like

|

| : 1.00 – 1.04

|

| : <1 mm

|

| : >1.0 N/mm²

|

| : >250%

|

| : 25 – 35

|

| : 5 – 15 Minutes

|

| 26 gm/L

|

| : -20 °C to 50 °C

|

| : Up to 150°C

|

|

|

|

|

| Applications

|

|

|

- General Glazing: Glass, fiberglass, plastic, aluminium, most painted and powder-coated materials.

- Curtain-wall Sealing: Glass, metal and plastic.

- General Sealing: Sheet Metal, Skylights, ventilators, air-conditioning.

- Ideal for glass sealing applications like aquarium.

|

|

|

| Directions

|

|

|

1. Surfaces must be clean, dry and free of dirt, grease, oil or water.

2. Surfaces should be cleaned with alcohol, M.E.K. or other suitable solvent. Do not use soap or detergent.

3. For a neat finish, apply masking tape and remove it before sealant skins over.

4. Cut nozzle at 45° angle to desired bead-width and apply to substrate with cartridge gun.

5. Tool the sealant within 5 minutes of extrusion before it skins. Tack-free in 15 minutes.

6. Uncured sealant can be cleaned up with mineral spirits.

7. Use approved backing material for joints over 10mm deep.

|

|

|

| Clean Up

|

|

|

- Wet sealants can be cleaned up with acetone or mineral spirits.

- Cured sealants can only be removed mechanically.

|

|

|

| Joint Design

|

|

|

- The specified sealant bead size should be calculated to comply with the compression and extension capabilities of the sealant in relation to the anticipated joint width due to expansion and contraction.

- Generally calculation of the width sealant bead should be computed on the basis of a maximum ±25 % movement capability

- Minimum joint depth should not be less than 6 mm to accommodate movement.

- Sealant design joint width-to-depth ratio should be 2:1.

|

|

|

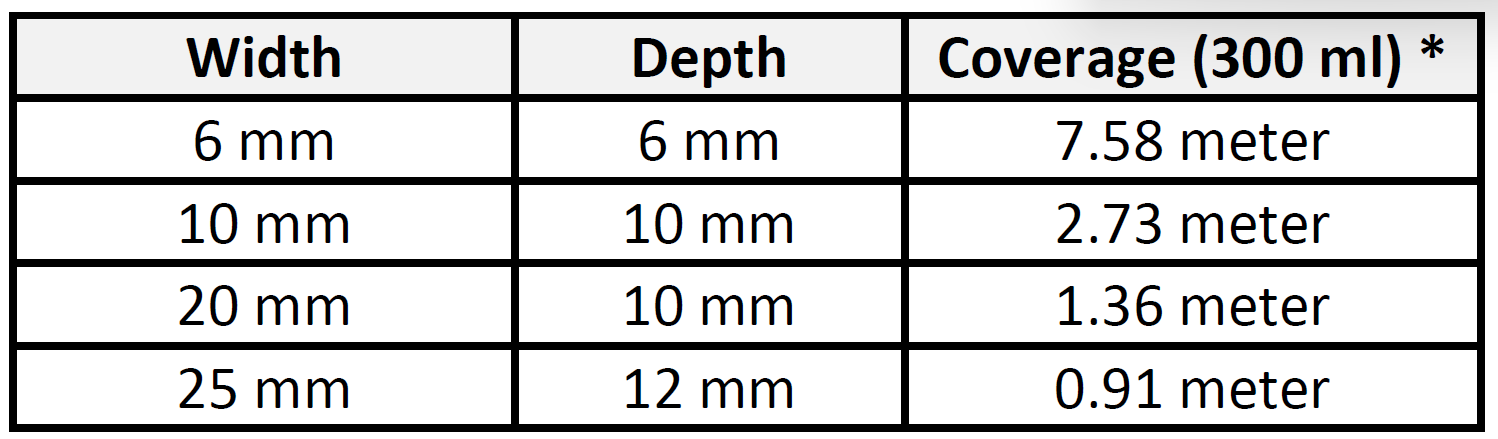

| Coverage

|

|

|

|

|

|

- The coverage figures shown above are approximate lineal meter run based on 10% wastage assumption. Actual coverage may vary.

- Calculation formula:

X / [(Y x Z) x 1.1] = Coverage

X = volume of cartridge (or sausage) in ml,

Y = joint width in cm, Z = joint depth in cm,

1.1 = 10% wastage assumption,

Coverage = lineal meter run in cm per cartridge (or sausage)

|

|

|

| Limitation

|

|

|

Not recommended for following applications:

- Substrates that could be corroded by acetic acid released as the sealant cures.

- Copper or any alloys containing copper.

- Polyethylene, polypropylene, and polytetrafluoroethylene (Teflon)

- Traffic areas subject to abrasion.

- Structural glazing.

- Substrates such as concrete, marble, quartzite, or natural stone.

- Neoprene rubber.

|

|

|

| Caution

|

|

|

| Product releases acetic acid during application and curing. Keep out of reach of children. Use in well ventilated areas. Safety data sheet available on request. For further health and safety information, consult the latest safety data sheet.

|

|

|