| Suitable For |

| |

- Apartments

- Bungalows

- Factory Buildings

- Hostels

- Long Houses

|

- Security Barracks

- Housing Projects

- School Buildings

- Shop Lots

|

|

|

|

| Benefits |

| |

- Very cost-effective to install with minimum support

- Low maintenance, highly durable and weatherproof

- Highly recommended for roof pitches from as low as 3 degree

- Provides superior water carrying capacity

- With a variety of pre-painted steel finishes offering long lasting beauty

|

|

|

|

| |

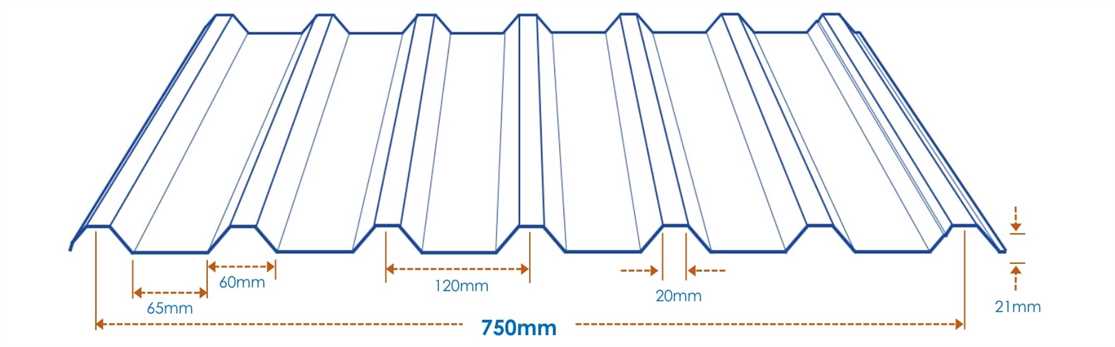

| Sectional dimension |

| |

| TOLERANCES : Length: 0-10mm | Width: +/-3mm | Thickness: +/-0.03mm |

| |

|

|

| |

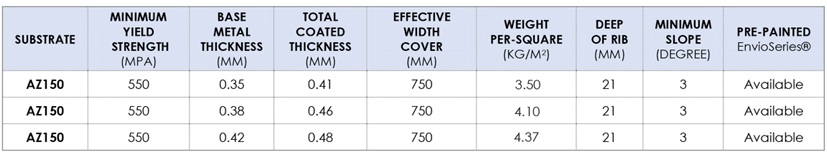

| Specification |

| |

|

| |

| Coating |

| |

| Different steels specifications for painted and unpainted also available on request. Total Coated Thickness values are nominal oly. |

| |

| Slope |

| |

| The recommended minimum slope is 3 degree. The amount of water that must be shed increases with the length of the roof. Therefore, to avoid possible back up of water in severe wind conditions, the recommended roof length should be considered as maximum for a given roof slope and rainfall rate. |

| |

| Lengths |

| |

| ZinSpan profile can be ordered in any length, subject to transport limitations. Longer lengths require special transport arrangements. |

| |

| Sheet Required |

| |

|

| |

| Recommended Maximum Support Spacing(MM) |

| |

.jpg) |

|

| |

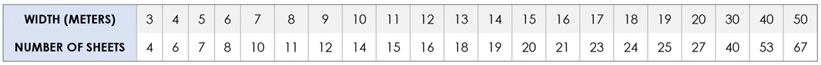

Material Options

|

| |

| ZinSpan profile is available in an attractive range of colours in EnvioSeries® pre-painted steel and in unpainted GaluZinc® coated steel. |

| |

|

| |

| GaluZinc® stands for aluminium and zinc, bonded in almost equal amounts to coat the steel sheet with a silvery spangle, composed of aluminium (55%), zinc (43.4%) and a touch of silicon (1.6%). GaluZinc® steel delivers outstanding anti-corrosion performance. |

|

|

.jpg) |

| |

| EnvioPrime® steel sheet is precisely developed to provide subtle performance for ZinSpan profile with content of the protective polish. |

|

|

|

| |

| EnvioClean® steel sheet is specifically designed with self-cleaning technology for ZinSpan profile surface where natural rain water is able to wash away dirt. |

|

|

|

| |

| EnvioMatt® is steel sheet specifically engineered for ZinSpan profile with stylish matt surface, suited to address the undesirable glare from sunlight. |

|

|

| |

| COLOUR SELECTION CHART |

| |

|

| |

| Colours |

| |

| All colours shown here approximate actual finish colurs as accurately as possible. It is recommended to order ZinSpan of the same colour at the same time to avoid slight colour differences between batches. |

| |

| Oil Canning |

| |

| Flat metal surfaces will display waviness commonly referred to as 'oil-canning'. This is caused by steel mill tolerances, variations in the substrate and roofing underlayments. Oil-canning is a characteristic, not a defect, of panels manufactured from light-gauge metal. Oil canning is not a cause for panel rejection. |

| |

| Certification |

| |

| With the cerlification of MS/ISO 9001:2015 Quality Management System, Jincorp Sdn. Bhd. ensures high quality EnvioSeries® and GaluZinc® steel are precisely cold formed into ZinSpan steel roofing sheet. |

|

| |

Warranty

|

| |

| Warranty Subject to application and eligibility criteria up for 30 years. There are various factors that will determine whether a building is eligible for a warranty and the duration of any applicable warranty. Such factors include, but are not limited to, product selection, environmental influences, manufacturing specifications and product specific requirements. |

| |

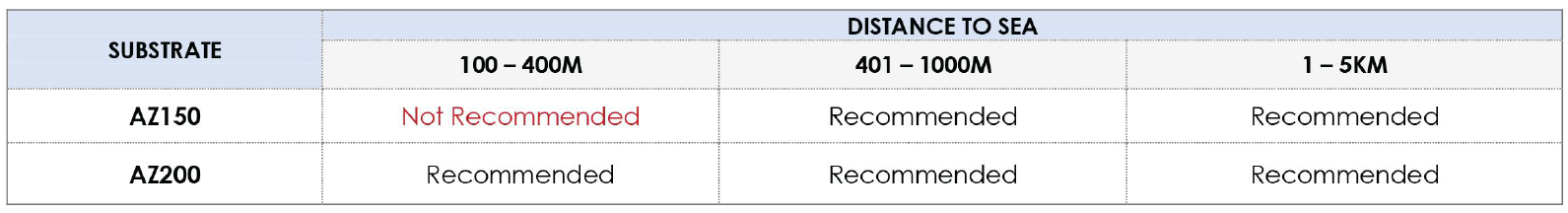

| Location |

| |

|

| |

| Substrate |

| |

| An AZ200 substrate is the most effective material available for harsh environment. |

|

| |

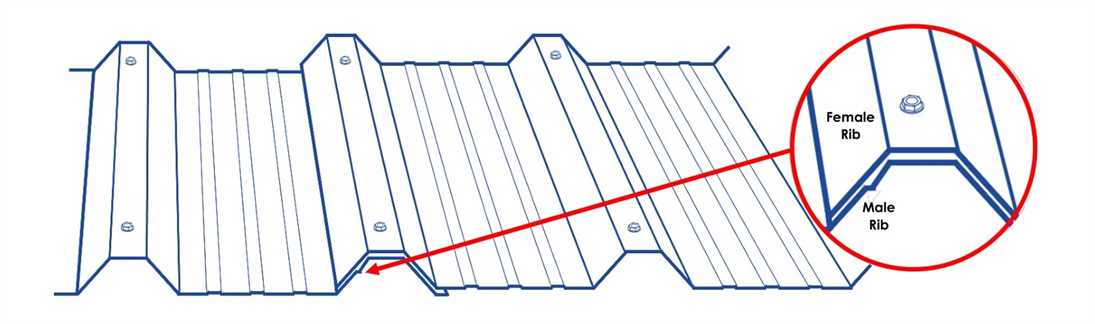

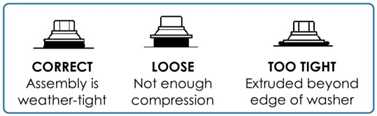

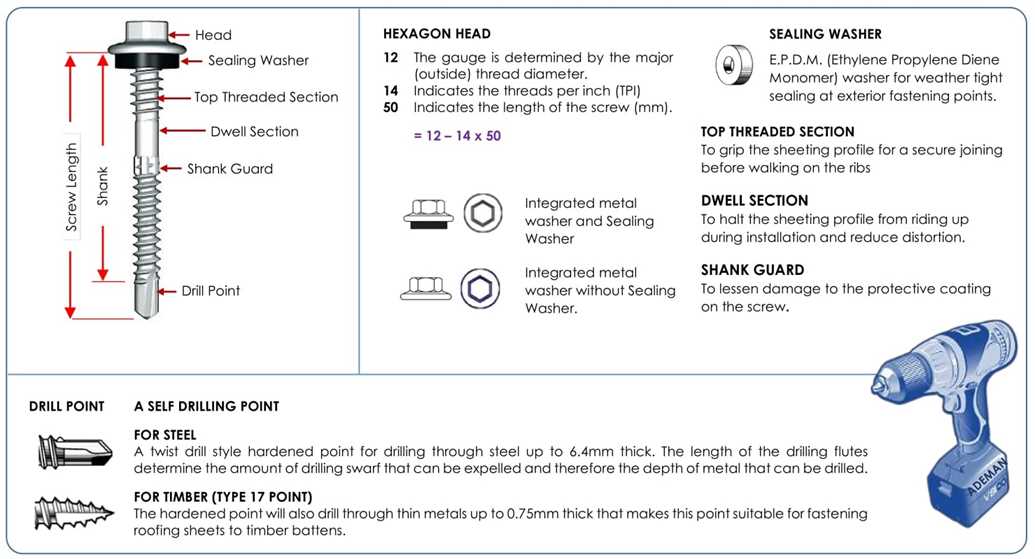

| ZinSpan is pierce-fixed to timber or steel supports using a power drill. This means that fastener screws pass through the sheeting. See the diagram below to understand how to install each fastener screw with the accurate side lapping of roofing sheets. |

| |

|

| |

| Crest Fixing |

| |

| To maximise roof water tightness, always place screws through the crests. Always drive the screws perpendicular to the sheeting, and in the centre of the corrugation or rib. |

|

|

|

| |

| Fasteners |

| |

| To match the performance of ZinSpan, the fastener must conform to AS 3566 Class 3 |

|

| |

| Cutting |

| |

| Before using a power saw with a metal cutting blade, ZinSpan profile coloured surface must be positioned facing the ground. No hot particles or debris allow to come into contact with the ZinSpan profile. |

| |

| Cleaning |

| |

| To prevent premature corrosion at the completion of each day ensure the sheeting area is cleared of all debris, including nais, rivets, rags and all cutting or drilling filings. |

| |

| Caution |

| |

| Green timber should not come into contact with EnvioSeries® pre-painted steel, due to acidic substances in the timber which have a corrosive effect on the coating. |

| |

| Turning Of Sheeting Ends |

| |

| It is common practice to overlap sheets into gutters by 50mm when the roof pitch is 25 degrees or in extreme weather areas. The pans of the sheets should be turned down at lower ends and turned up at upper ends. |

|

| |

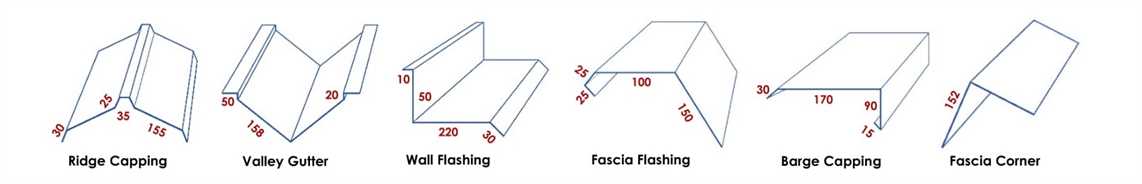

Accessories

|

| |

| Accessories are available to match ZinSpan profile. |

| |

|

| |

| Width And Length |

| |

| Widths (mm) are fixed for every flashing and capping profile. Factory standard length is 8 feet. |

| |

| Compatibility |

| |

| Each falshing or capping profile should be made from the same material as the material used for ZinSpan profile. |

| |

| Caution |

| |

| Copper and Lead are incompatible materials and should NOT be used with ZinSpan profile made from EnvioSeries® steel. |

| |

Other Profiles

|

| |

|

| |

| REQUEST A QUOTE: Provide us with a few details about your next project, and we'll prepare a no-obligation update. We look forward to the opportunity of partnering together. |

| |

Workmanship

|

| |

SAFETY SAFETY

Always work safety when installing metal products and use extreme caution on the roof at all times. Wear gloves and safety glasses to reduce the risk of injury, and use hearing protection when operating power tools. Alaways wear smooth soft-soled shoes; avoid ribbed soles that pick up and hold small stones, swart and other objects.

CARE AND STORAGE CARE AND STORAGE

Store metal panels indoors when possible; if outdoors; cover and elevate. Elevate one side higher for water drainage. Never cover in plastic. If a bundle gets wet, break bands and separate sheets; allow sheets to dry completely and only restack if completely dry. Material should be used promptly (within 3 months) to avoid the possibility of a storage related corrosion.

HANDLING HANDLING

It is recommended that heavy-duty cut-resistant gloves and appropriate manual handling techniques or a lifting plan be used when handling material. Handle materials carefully to avoid damage: don't drag materials over rough surfaces or each other; protect from swarf. |

| |

References

|

| |

|

|

| |

|