| PRIMA drywall is a wall system which comprises of PRIMA liner fibre cement boards fixed onto galvanised steel stud and track frames that can be erected in a fully (100%) dry condition without the need for cement mortar plastering. PRIMA drywall system acoustic, heat and fire resistant standards can be improved by adding mineral wool as the insultation material. Moreover the system is designed to meet the Malaysia Uniform Building By-Laws (UBBL) & BOMBA requirements. |

Please enter valid quantity.

Product Description

|

|

| Suitable For

|

|

|

- Fire-Rated (BOMBA)

- Cost Effective

- Space Efficient

- CONQUAS & QLASSIC Standards

- Better Site Management, Low Wastage

|

|

|

- Fast & Lightweight (IBS)

- Simple Construction Method

- Solid, Strong & Secured (BS 5234, Part 2)

- High STC & Thermal Resistant

- No Stiffeners Required

|

|

|

|

|

|

|

| Recommended Applications

|

|

|

| Fire-Rated

|

|

|

| Non Fire-Rated

|

- General Area

- Wet Area

- Internal & External Walls

|

|

|

| Performance & Robustness

|

|

|

- IBS factor : 1.0

- Severe Duty (BS 5234:Part 2)

- Adhered to CONQUAS & QLASSIC surface evenness requirements

- Installation speed 5 times daster than brick wall

|

|

|

|

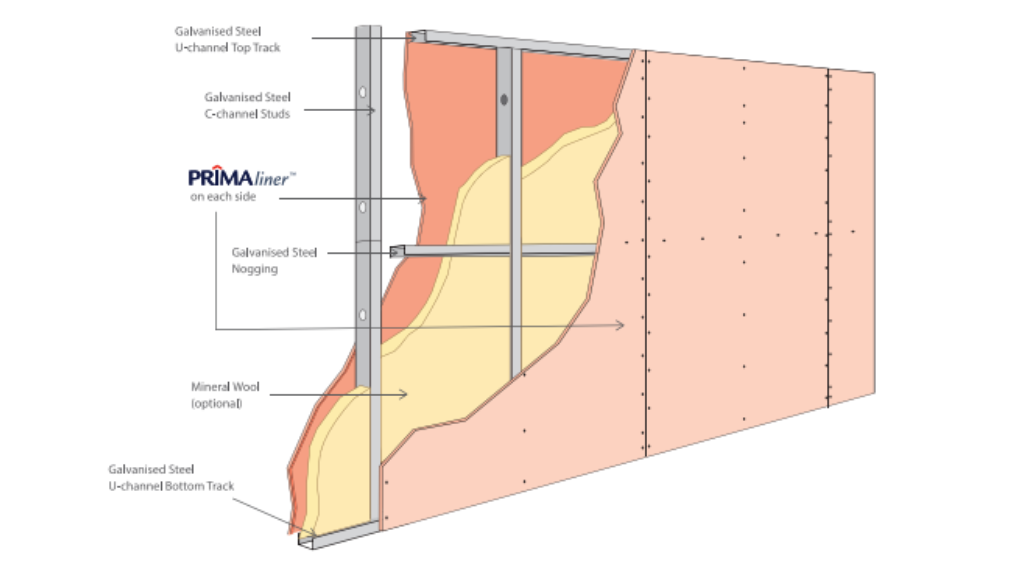

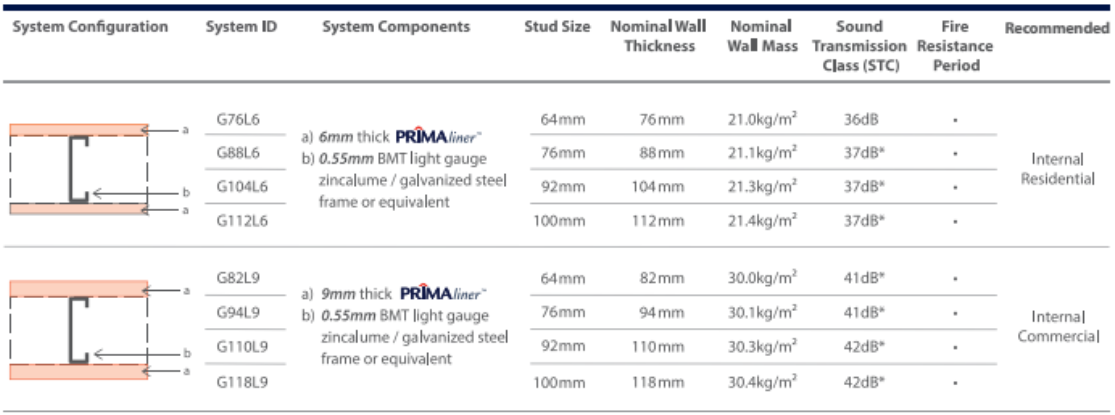

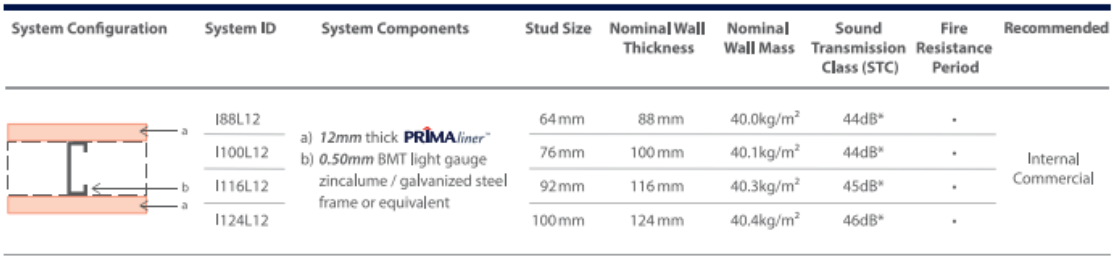

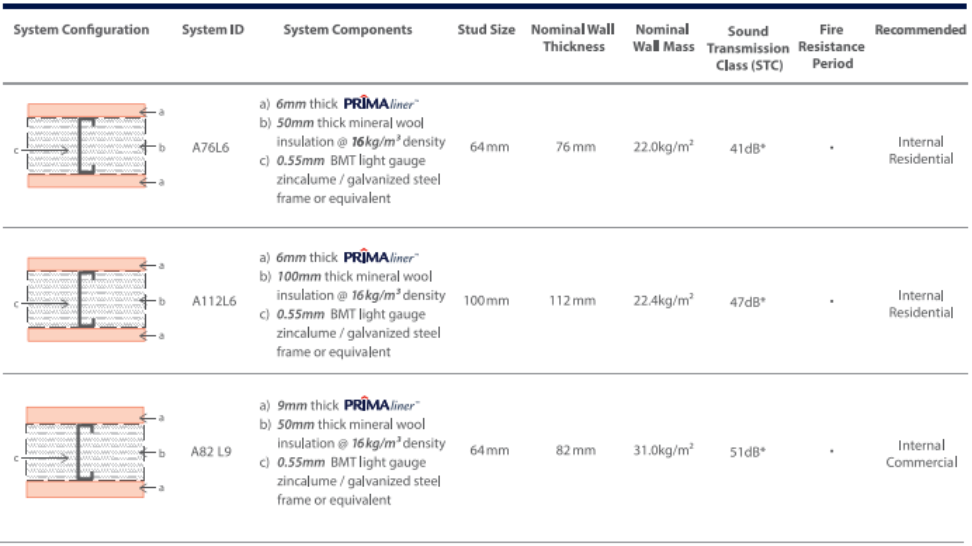

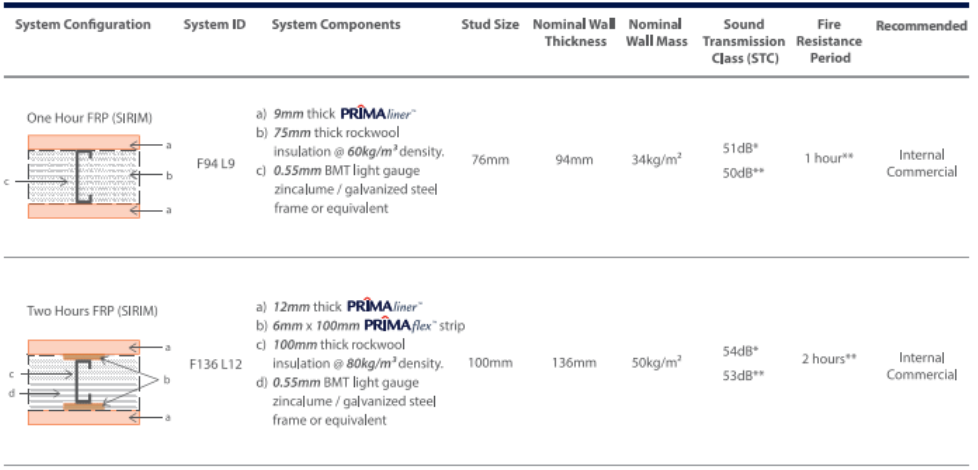

| System Overview

|

|

|

|

|

|

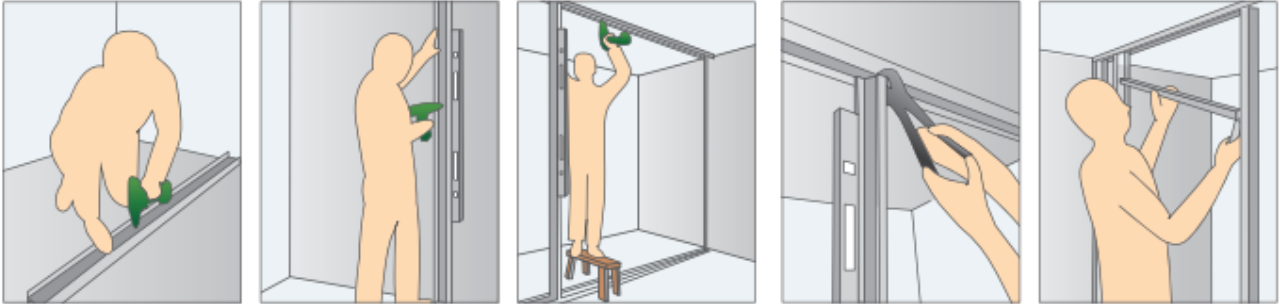

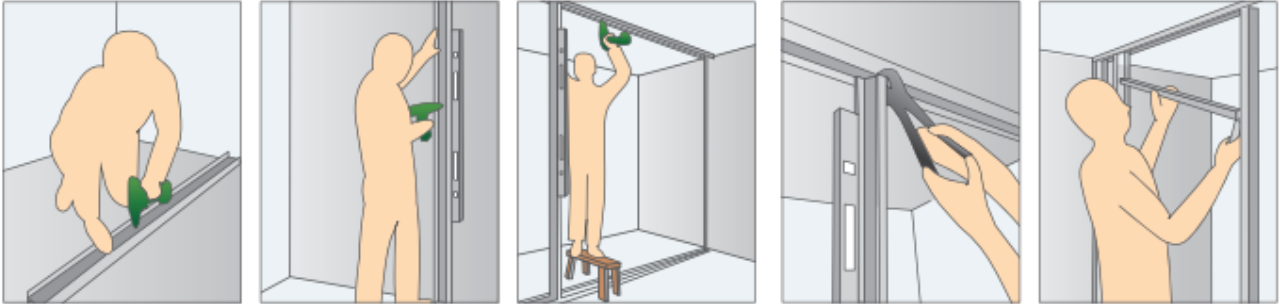

| How To Install ?

|

|

|

|

|

|

|

|

|

1. Set the wall position fix the soffit & floor tracks (U Tracks).

2. Fix the intermediate wall studs (C Stud).

3. Fix door frame & window frame.

4. Install the 1st layer of PRIMA Liner board.

5. Fix M&E services.

|

6. Insert mineral wool (optional)

7. Insert 2nd layer of PRIMA Liner board

8. Flush jointing & patching of fastener.

9. Finishes.

|

|

|

|

| The wall is complete and ready for painting, texture coating, wallpaper or even tiling application.

|

|

|

|

|

| Suitable For

|

|

|

- Fire-Rated (BOMBA)

- Cost Effective

- Space Efficient

- CONQUAS & QLASSIC Standards

- Better Site Management, Low Wastage

|

- Fast & Lightweight (IBS)

- Simple Construction Method

- Solid, Strong & Secured (BS 5234, Part 2)

- High STC & Thermal Resistant

- No Stiffeners Required

|

|

|

|

| Recommended Applications

|

|

|

| Fire-Rated

|

|

|

| Non Fire-Rated

|

- General Area

- Wet Area

- Internal & External Walls

|

|

|

|

|

| Performance & Robustness

|

|

|

- IBS factor : 1.0

- Severe Duty (BS 5234:Part 2)

- Adhered to CONQUAS & QLASSIC surface evenness requirements

- Installation speed 5 times daster than brick wall

|

|

|

|

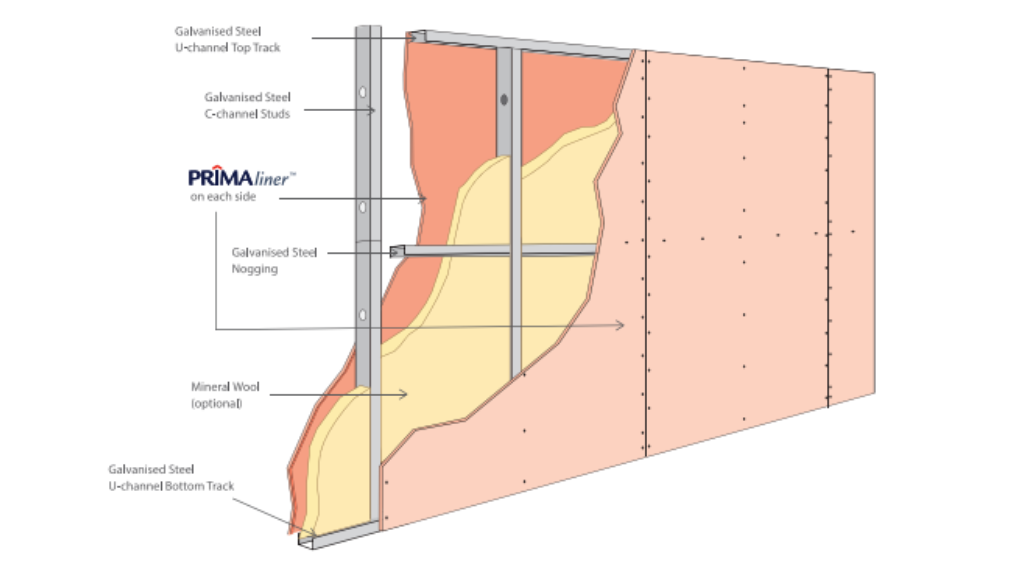

| System Overview

|

|

|

|

|

|

| How to install ?

|

|

|

|

|

|

|

|

|

1. Set the wall position fix the soffit & floor tracks (U Tracks).

2. Fix the intermediate wall studs (C Stud).

3. Fix door frame & window frame.

4. Install the 1st layer of PRIMA Liner board.

5. Fix M&E services.

|

6. Insert mineral wool (optional)

7. Insert 2nd layer of PRIMA Liner board

8. Flush jointing & patching of fastener.

9. Finishes.

|

|

|

|

| The wall is complete and ready for painting, texture coating, wallpaper or even tiling application.

|

|

|

|

| General

|

|

|

|

|

|

| Impact

|

|

|

|

|

|

| Acoustic

|

|

|

|

|

|

| Fire-Rated

|

|

|

|

|

|

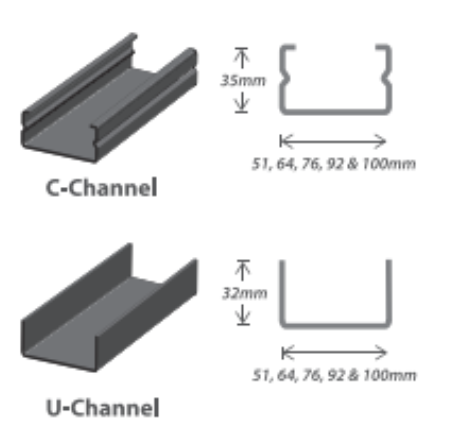

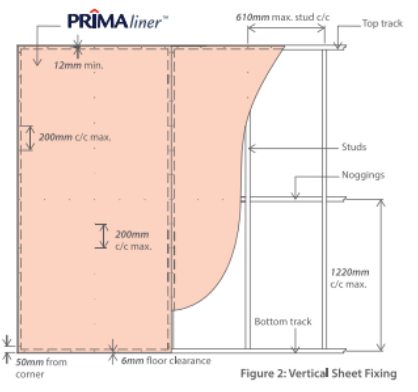

| Framing

|

|

|

| Framing member must be fabricated using light gauge galvanised coated (or equivalent) steel sections having a minimum of 0.55mm base metal thickness with spacing not exceding the following spacing distance:

|

|

|

- Wall studs - 610 mm c/c maximum

- Noggings - 1220 mm c/c maximum

|

| The actual studs and noggings sizes shall be selected based on the above table. A fire rating or (and) sound insultation is required, refer to "System Comonents & Properties" table for additional requirements.

|

|

|

|

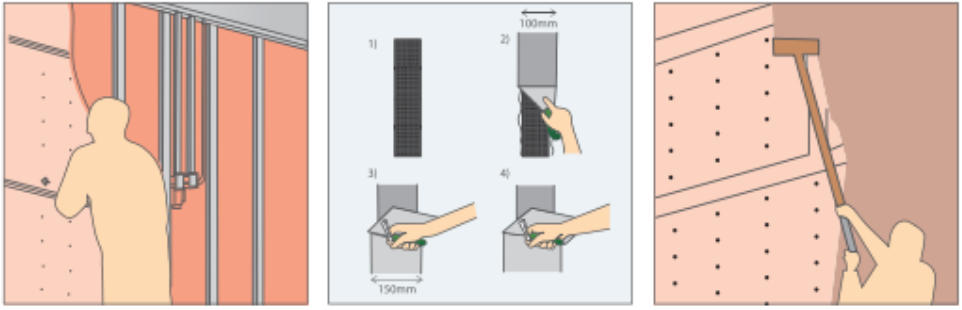

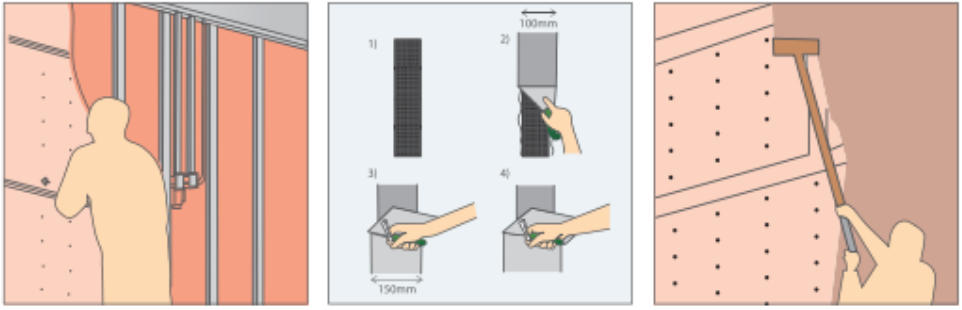

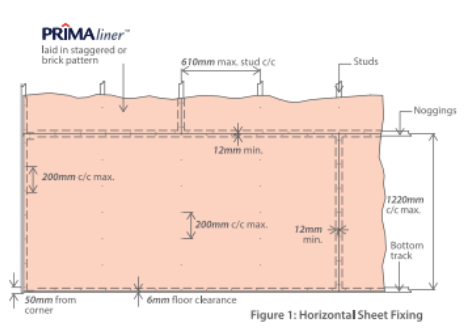

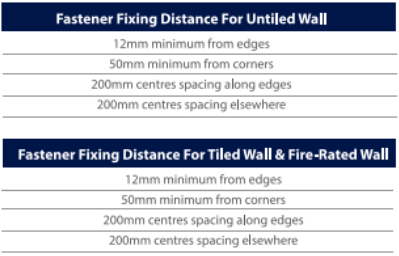

| Sheet Installation & Fastening requirement

|

|

|

| In drywall construction, PRIMA Liner can be installed horizontally or vertically. The sheets must be laid staggered and ensure the sheet joints on one side of the wall do not coincide with the sheet joints on the other side of the wall.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

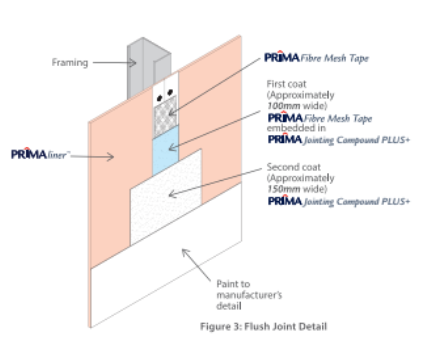

| Joint Details

|

|

|

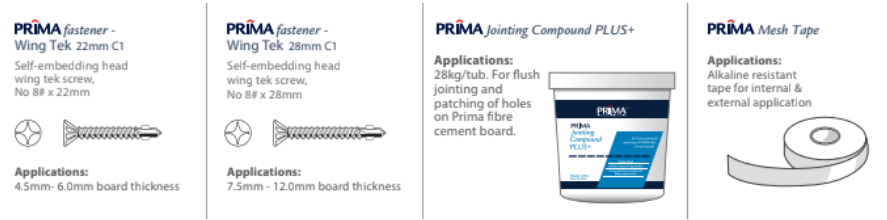

| PRIMA Liner sheet joints can be treated as described in the Figure 3 incorporating PRIMA Fibre Mesh Tape and PRIMA Jointing Compound PLUS+. The best result can be achived when both PRIMA Liner edges have recesses. Jointing non-recessed edges should be avoided.

|

|

|

|

|

|

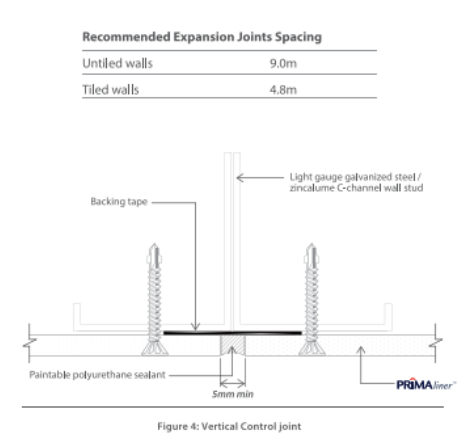

| Expansion Joint

|

|

|

| Expansion joints must be provided to accomodate anticipated movement within a buiding. PRIMA drywall system require expansion joints to be located as follow:

|

|

|

|

|

|

| Finishes

|

|

|

| PRIMA Liner can be decorated with 2 coats of 100% quality water-based Arclic Paint. For general-purpose applications, there is no requirement for Primers or Sealers. Alternatively, the sheet surface can be decorated with wall covering materials, such as Wallpaper. In all cases, coating manufacturer's recommendations must be strictly adhered to. For wet area application, water proofing and tile finishing may be preferred.

|

|

|

- The flexible Tile Adhesive shall comply to AS 2358-1990; Adhesive for ceramic wall tiles & mosaics.

- The choice of the Tile Adhesive varies, depending on the substrate and the type of tiles used. Refer to Tile Adhesive manufacture for advice.

- DO NOT tile over Expansion Joint.

- Expansion Joint should be sealed with flexible water-resistant Acrylic Sealant for general & wet area walls. Fire-rated seal is recommended for fire-rated walls.

- For wet area application, use cementitious Jointing Compound with alkaline-resistant fibre glass reinforcement tape to treat the sheet joints and finished with a layer of water-proofing coating on top before applying wall tiles.

|

|

|

|

|

|

| Accessories

|

|

|

|

|

|

|

Frequently Purchase Together