| Features

|

|

|

- Neutral curing system

- Excellent adhesion

- Permanently flexible

- Excellent weather resistance

- Indoor and outdoor use

|

|

|

|

| Available Colors

|

|

|

- Translucent (BS-2530)

- Dark Bronze (BS-2530)

- White (BS-2530C)

- Black (BS-2530C)

- Grey (BS-2530C)

- Dark Grey (BS-2530C)

|

|

|

|

|

|

| Packaging

|

|

|

.png)

|

|

|

| Storage

|

|

|

- Store in a dry and cool place with temperature below 30 °C.

- Use within 12 months from date of production.

|

|

|

|

| Product Specification

|

|

|

|

|

| Curing System

|

Appearance

|

| Density

|

| Slump (ASTM D2202)

|

| Maximum Tensile Strength (ASTM D412)

|

| Elongation at Break (ASTM D412)

|

| Shore A Hardness (ASTM C661)

|

| VOC Content (USEPA Test Method 24)

|

| Tack-free Time (at 25 °C & 50% R.H.)

|

| Application Temperature

|

| Service Temperature

|

|

| BS-2530

|

| : Oxime

|

: Non-Sagging Paste (Before Curing)

: Elastic Rubber (After Cured)

|

| : 0.99 g/mL

|

| : <1 mm

|

| : 1.3 N/mm²

|

| : 380 %

|

| : 23

|

| : 108.95 g/L

|

| : 10 – 30 minutes

|

| : -20 °C to 50 °C

|

| : Up to 150°C

|

|

| BS-2530C

|

| : Oxime

|

: Non-Sagging Paste (Before Curing)

: Elastic Rubber (After Cured)

|

| : 1.34 g/mL

|

| : <1 mm

|

| : 1.3 N/mm²

|

| : 320 %

|

| : 37

|

| : 88.10 g/L

|

| : 10 – 30 minutes

|

| : -20 °C to 50 °C

|

| : Up to 150°C

|

|

|

|

|

| Applications

|

|

|

| Well-suited for sealing metal lap joints in roofing, guttering and cladding applications. It will bond to form a strong weatherproof seal on most common building materials such as aluminum, galvanized and zinc-coated steel, painted surfaces, glass, brick, and concrete. It is suitable for both indoor and outdoor applications.

|

|

|

| Directions

|

|

|

1. Surfaces must be clean, dry and free of dirt, grease, oil or water.

2. Surfaces should be cleaned with alcohol, M.E.K. or other suitable solvent. Soap or detergent and water treatments are not recommended.

3. For a neat finish, apply masking tape and remove it before sealant skins over.

4. Cut nozzle at 45° angle to desired bead-width and apply to substrate with cartridge gun.

5. Tool the sealant within 10 minutes of extrusion before it skins. Tack-free in 20 minutes.

6. Uncured sealant can be cleaned up with mineral spirits.

7. Use approved backing material for joints over 10mm deep.

|

|

|

| Clean Up

|

|

|

- Wet sealants can be cleaned up with acetone or mineral spirits.

- Cured sealants can only be removed mechanically.

|

|

|

| Joint Design

|

|

|

- The specified sealant bead size should be calculated to comply with the compression and extension capabilities of the sealant in relation to the anticipated joint width due to expansion and contraction.

- Generally calculation of the width sealant bead should be computed on the basis of a maximum ±20 % movement capability

- Minimum joint depth should not be less than 6 mm to accommodate movement.

- Sealant design joint width-to-depth ratio should be 2:1.

|

|

|

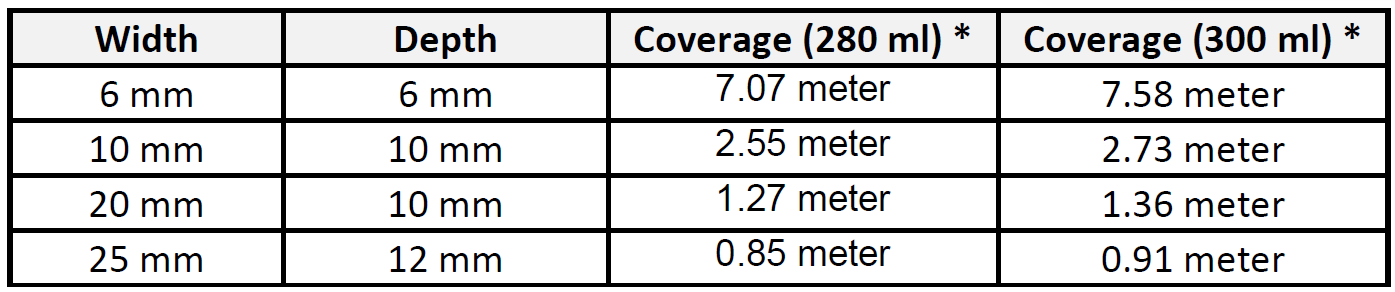

| Coverage

|

|

|

|

|

|

- The coverage figures shown above are approximate lineal meter run based on 10% wastage assumption. Actual coverage may vary.

- Calculation formula:

X / [(Y x Z) x 1.1] = Coverage

X = volume of cartridge (or sausage) in ml,

Y = joint width in cm, Z = joint depth in cm,

1.1 = 10% wastage assumption,

Coverage = lineal meter run in cm per cartridge (or sausage)

|

|

|

| Limitation

|

|

|

Not recommended for following applications:

- Structural glazing applications.

- Below waterline or permanent water immersion.

- Traffic areas subject to abrasion.

- Polycarbonate and polyacrylate, if under tension.

- Applications that requires the sealant to be painted.

- Neoprene rubber.

|

|

|

| Caution

|

|

|

| Product releases methylethylketoxime during application and curing. May cause an allergic skin reaction. Causes serious eye irritation. Wear protective gloves and eye protection. IF ON SKIN: Wash with soap and water. IF IN EYES: Rinse continuously with water for several minutes. Remove contact lenses if present and easy to do – continue rinsing. If skin irritation or a rash occurs: Get medical advice/attention. If eye irritation persists: Get medical advice/attention. Wash contaminated clothing before reuse. Keep out of reach of children. Contains aminosilane. May produce an allergic reaction. Safety data sheet available on request. For further health and safety information, consult the latest safety data sheet.

|

|

|